Sheet Metal Punching Services

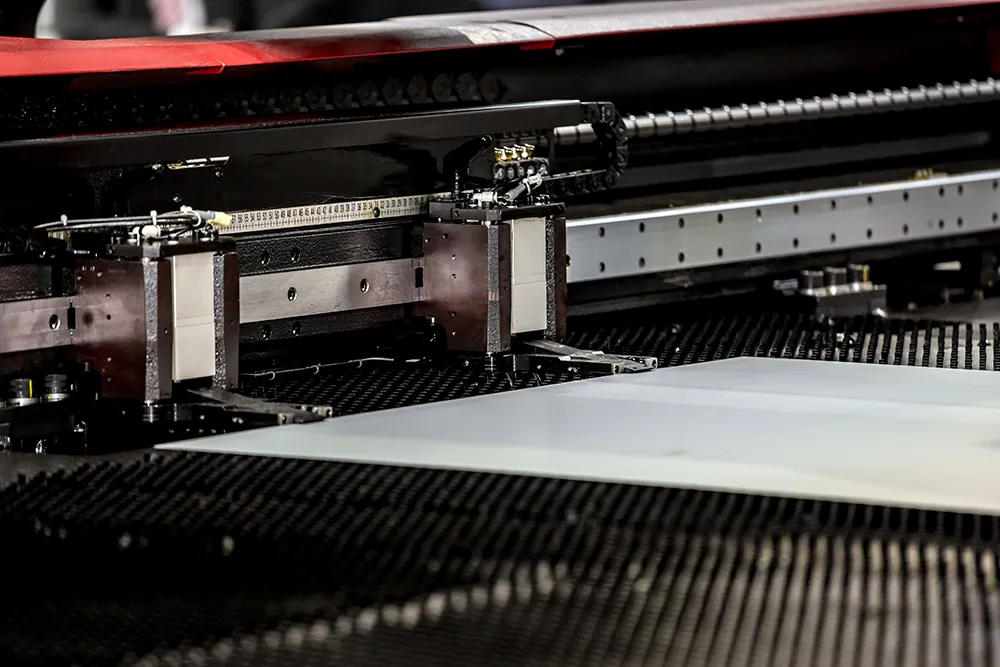

Efficient and Cost-Effective Punching Solutions

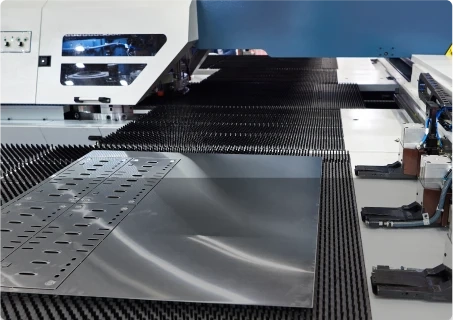

LMI Manufacturing delivers precision sheet metal punching solutions designed to enhance efficiency, accuracy, and affordability for your projects. Leveraging our extensive in-house tooling library—nearly 1,000 custom punch tools—we ensure rapid turnarounds and significant cost savings.

Our Sheet Metal Punching Capabilities

Utilizing advanced CNC turret punch technology, LMI accurately processes sheet metal components for a variety of applications. Our comprehensive tooling library enables us to quickly meet your unique requirements without the added expense of creating new tools.

Stainless Steel

Aluminum

Carbon Steel

Industries We Serve

LMI Manufacturing delivers high-quality sheet metal punching solutions to diverse markets, including:

Electrical Cabinets

Agricultural Equipment

Industrial

Machinery

Material Handling Systems

Data Centers

Medical Cabinets

Turret Punch: Capabilities

Max. Sheet Size (X, Y): 100” x 39”

Max. Axis Travel (X, Y): 39&rdquo x 50&rdquo

Table Speed (X, Y combined): 1,968”/min

Turret Stations: 58

Turret Rotation per Min: 30 RPM

Stroke per Min: 350/min

Hits per Min: (1” Centers) 200 Hpm

Benefits of Our Punching Services

- Cost Savings: Avoid tooling costs with our extensive, existing punch library.

- Quick Turnaround: Accelerated project completion with reduced setup times.

- Accuracy & Consistency: Precision punching for high-quality, consistent results.

- Experienced Technicians: Skilled professionals ensuring each component meets stringent standards.

Past Project Highlights

We've successfully partnered with clients across multiple industries, providing precision laser cutting solutions that meet stringent specifications and deadlines. Our focus on collaborative problem-solving and adaptability ensures each project achieves exceptional outcomes.

Why Choose LMI for Sheet Metal Punching?

With over six decades of manufacturing expertise, LMI is your trusted partner for reliable, high-quality sheet metal punching services. Our advanced equipment, extensive tooling options, and commitment to excellence help streamline your projects while reducing overall costs.

Frequently Asked Questions

Our extensive tooling inventory allows rapid turnaround, significantly reducing lead times compared to industry standards.

Absolutely! Our skilled team specializes in custom and complex punching projects tailored specifically to your needs.

We accommodate a range of volumes, focusing on mid-volume runs designed to provide optimal cost-efficiency.

Ready to Start Your Project?

Experience the advantages of our precision punching services firsthand.