Roll Forming Services

Efficient Roll Forming Solutions Tailored to Your Specifications

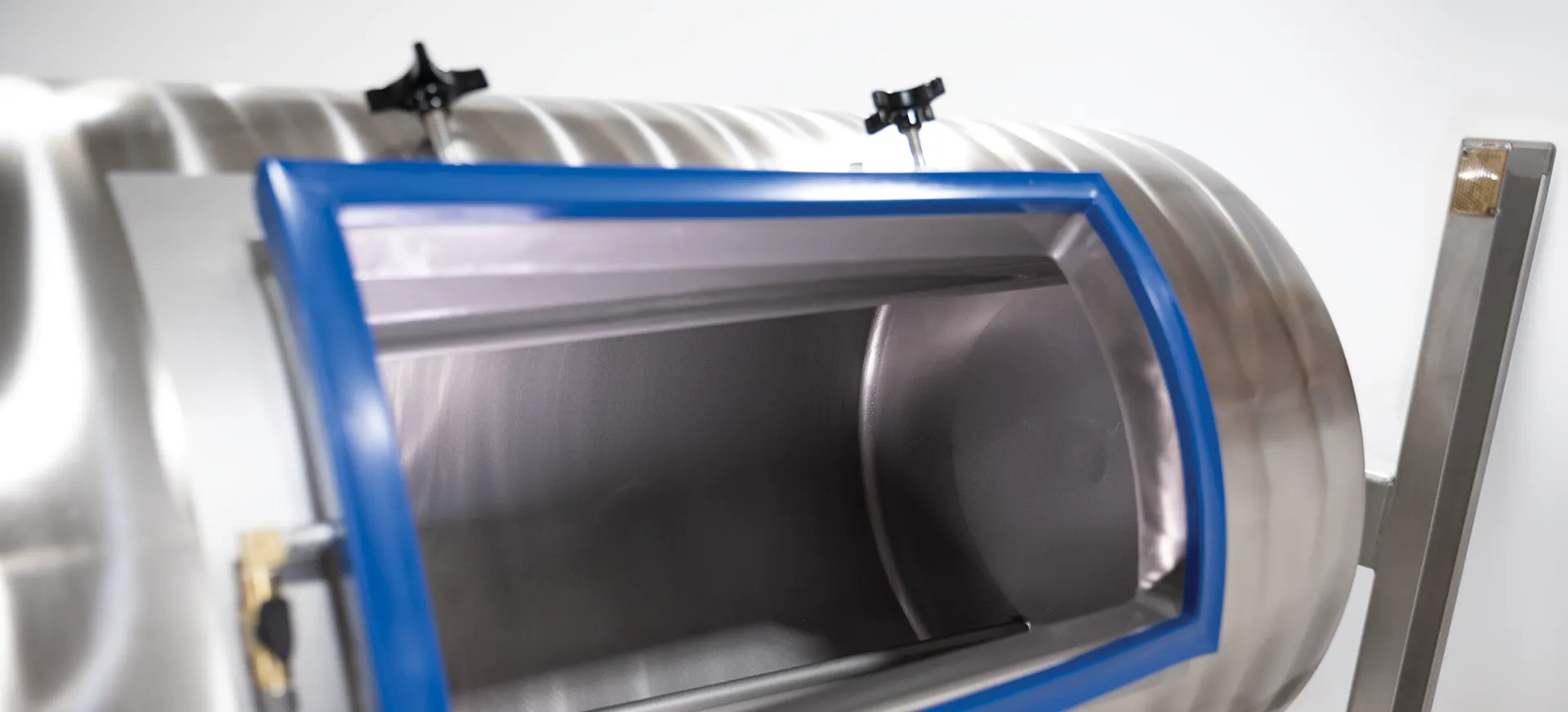

LMI Manufacturing provides expert roll forming services to efficiently produce high-quality metal components with uniform cross-sections. Our precision roll forming processes deliver consistent results, making them ideal for cost-effective, repeatable production needs.

Materials We Roll Form

Steel

Aluminum

Stainless Steel

Galvanized Steel

Roll Forming Capabilities

- Consistent, accurate shapes for uniform profiles

- Cost-effective manufacturing for repetitive parts

- Capability to handle various thicknesses and widths

Industries Benefiting from Our Roll Forming

Construction

Material Handling Systems

Food Processing

Industrial Components

Agricultural Equipment

Why Partner with LMI for Roll Forming?

Choosing LMI Manufacturing ensures efficient roll forming services supported by decades of industry experience and advanced equipment. Our commitment to quality and accuracy means you get reliable and cost-effective solutions tailored precisely to your project's specifications.

Past Project Highlights

We've successfully partnered with clients across multiple industries, providing precision laser cutting solutions that meet stringent specifications and deadlines. Our focus on collaborative problem-solving and adaptability ensures each project achieves exceptional outcomes.

Advantages of LMI’s Roll Forming

- Consistent Quality: Reliable results with minimal variation, ensuring high-quality production runs.

- Cost Efficiency: Reduced labor and material costs for large volume runs.

- Rapid Turnaround: Streamlined processes to minimize lead times.

Frequently Asked Questions

Roll forming is ideal for producing parts that require uniform cross-sectional profiles, such as frames, channels, rails, and similar repetitive components.

Yes, we specialize in custom projects and can tailor roll forming services to meet specific client requirements.

Roll forming is highly cost-effective for repetitive, high-volume parts, providing consistent shapes with excellent precision and minimal waste.

Ready to Get Started?

Experience efficient, high-quality roll forming solutions with LMI Manufacturing.