Panel Bending Services

Precision Panel Bending Solutions for Complex Components

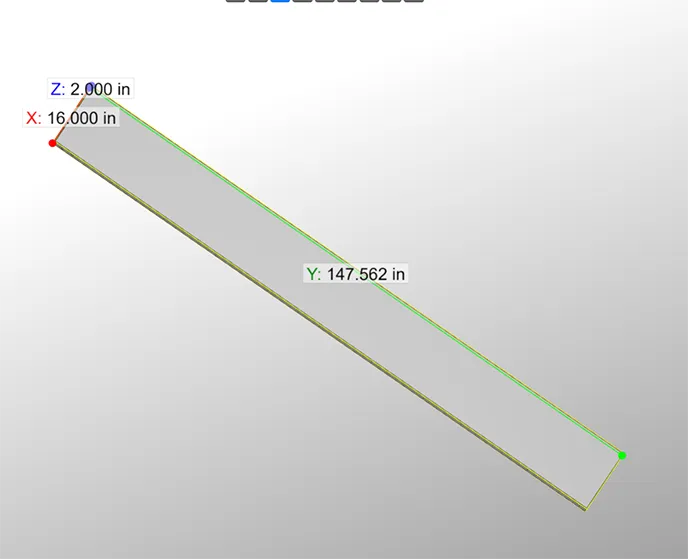

LMI Manufacturing provides advanced panel bending services designed for accuracy, efficiency, and repeatability. Panel bending is ideal for producing complex geometries, especially when parts require multiple bends, high consistency, and shorter cycle times. Our skilled technicians and modern equipment ensure reliable results across both prototype and mid-volume production runs.

Materials We Panel Bend

Aluminum

Stainless Steel

Carbon Steel

Galvanized Steel

Panel Bending Capabilities

- High repeatability for large batches of similar components

- Ability to produce multiple bends on the same part quickly

- Ideal for parts requiring complex geometries or intricate folds

- Efficient handling of both thin sheet and thicker metals

- Reduced tooling requirements compared to traditional press brakes

Industries Benefiting from Our Panel Bending

Electrical Cabinets

Agriculture

Data Centers

Medical Cabinets

Construction

Industrial Components

Why Partner with LMI for Panel Bending?

With more than 60 years of fabrication expertise, LMI Manufacturing combines technical know-how with advanced equipment to deliver precise and efficient panel bending solutions. Our collaborative approach means we work alongside you to optimize designs for manufacturability, reduce lead times, and improve overall quality.

Past Project Highlights

We've successfully partnered with clients across multiple industries, providing precision panel bending solutions that meet stringent specifications and deadlines. Our focus on collaborative problem-solving and adaptability ensures each project achieves exceptional outcomes.

Advantages of LMI’s Panel Bending

- Consistency & Accuracy: Repeatable results across multiple production runs.

- Design Flexibility: Accommodates complex bends and part geometries.

- Cost-Effective: Reduced tooling changes streamline production.

- Fast Turnaround: Efficient processes help you hit deadlines.

Frequently Asked Questions

Press brakes are ideal for one-off or custom bends, while panel bending excels at repetitive, multi-bend parts where consistency and speed are critical.

Yes, our team regularly assists with prototypes and transitions designs into repeatable production runs.

Industries that require consistent, complex parts—such as electrical equipment, transportation, and construction—find panel bending especially valuable.

Need different forming options? Check out our Sheet Metal Forming and Roll Forming services.

Ready to Start Your Project?

Turn to LMI Manufacturing for precise, efficient panel bending services tailored to your needs.