Machining Services

Precision Machining Solutions Tailored for Your Project

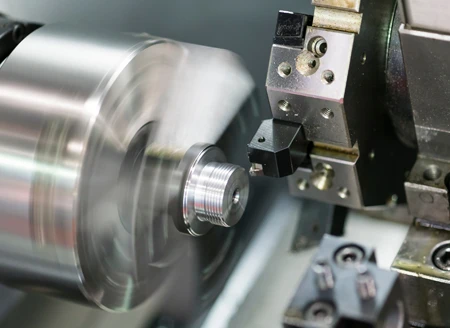

LMI Manufacturing offers high-precision machining services, providing meticulously crafted components designed to meet your most stringent specifications. Our skilled technicians and state-of-the-art equipment ensure consistency, accuracy, and exceptional quality in every project.

Our Machining Capabilities

CNC Milling

CNC Turning

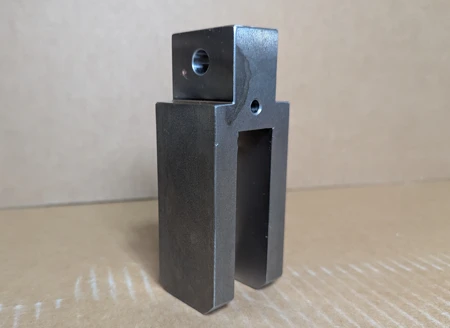

Custom Machining Solutions

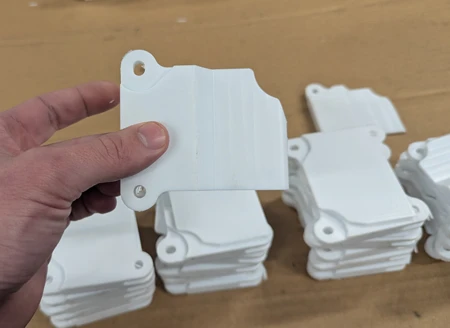

Prototype to Production Machining

Precise Tolerance Control

Materials & Thickness Capabilities

Smart Fabrication. Transparent Process. Real Results.

When you're under pressure to deliver-whether for a build, a PO, or a production ramp-we're the supplier that shows up and makes it happen.

Stainless Steel

Aluminum

Carbon Steel

Copper

Brass

Plastic

Industries We Serve

Data Centers

Industrial

Equipment

Food Processing

Electrical

Components

Medical & Healthcare

Cabinets

Agricultural &

Construction

Our Machines

HAAS VF-4 SS

Table Size: 52.0" x 19.5"

Travels (XYZ): 50" x 20" x 25"

Spindle Speeds: 100 to 12000 RPM

Rapid Traverse (XYZ): 1400 IPM

Max Cutting: 833 IPM

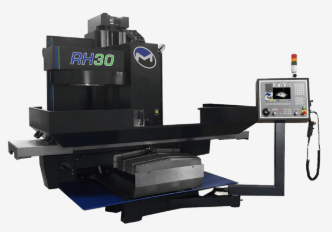

Milltronics Model RH30

Table Size: 73" x 24"

Travels (XYZ): 60" x 30" x 28"

Spindle Speeds: 100 to 8000 RPM

Rapid Traverse (XYZ): 500 IPM

HAAS VF-4 Milling Center

Table Size: 40" x 19”

Travel (XYZ): 50” x 20” x 25”

Spindle Nose to Table: 4” – 29”

Rapid Traverse Rates: 710 IPM

Spindle Speed: 0 – 7,500 RPM

HAAS SL-20T CNC Lathe

Travel (XZ): 8.45” x 20”

Rapid Traverse (XZ): 710IPM

Spindle Bore: 3.02”

Spindle Speeds: 50 – 3400 RPM

Max Turning Diameter: 10”

Max Turning Length: 20”

Max Bar Capacity: 2”

Swing Over Bed: 23”

Manual Lathes

Why Partner with LMI for Machining?

Choosing LMI Manufacturing for your machining needs ensures that every component is produced to the highest standards. Our expertise in precision machining, combined with advanced equipment and processes, delivers consistent results, quality assurance, and cost-effective solutions.

Past Project Highlights

We've successfully partnered with clients across multiple industries, providing precision laser cutting solutions that meet stringent specifications and deadlines. Our focus on collaborative problem-solving and adaptability ensures each project achieves exceptional outcomes.

Benefits of LMI's Machining Services?

- High Accuracy: Exceptional precision meeting tight tolerances.

- Rapid Turnaround: Streamlined in-house processes reduce lead times.

- Cost Efficiency: Competitive pricing, optimized material usage, and minimized waste.

- Skilled Expertise: Experienced machinists dedicated to quality craftsmanship.

Frequently Asked Questions

We specialize in prototype to mid-volume production, ensuring efficiency, accuracy, and cost-effectiveness tailored to your needs.

We machine a wide range of materials including aluminum, stainless steel, carbon steel, brass, copper, and various plastics.

Please provide CAD files such as SolidWorks, AutoCAD, .dwg, or PDF files for accurate quoting and project planning.

Ready to Start Your Project?

Experience precision and reliability with machining services from LMI Manufacturing. Your project deserves exceptional results.