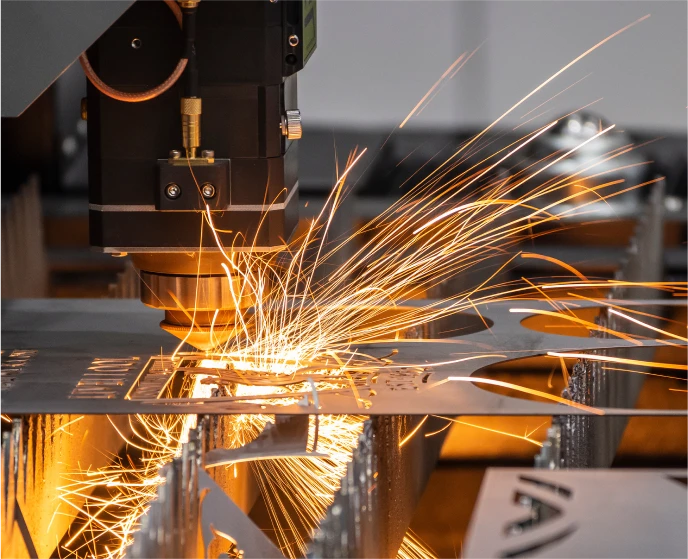

Laser Cutting Services

Precision Laser Cutting Services Tailored to Your Needs

At LMI Manufacturing, our team pairs decades of fabrication experience with advanced CNC and fiber laser cutting technology to deliver precise, efficient results. Using a 6kW laser cutting machine, we process sheet metal and large components up to 158" × 79" with speed, accuracy, and consistency for every project. Whether you're working with small-scale brackets or oversized components, we’ve got the equipment and team to get the job done right.

Materials & Thickness Capabilities

Smart Fabrication. Transparent Process. Real Results.

When you're under pressure to deliver-whether for a build, a PO, or a production ramp-we're the supplier that shows up and makes it happen.

Stainless Steel

Aluminum

Carbon Steel

Copper

Brass

Industries We Serve

LMI Manufacturing provides custom laser cutting solutions to OEMs across diverse industries. From data centers and electrical equipment to food processing, medical, and industrial machinery, our metal laser cutting capabilities support precise, repeatable production across all markets.

Data Centers

Construction &

Agriculture

Food Processing

Medical & Healthcare

Cabinets

Advantages of LMI's Laser Cutting Services

- Precision & Quality: Our advanced fiber laser cutting system delivers clean edges, tight tolerances, and reliable accuracy for every project.

- Fully Integrated Capabilities: Our facility includes 12-ft press brakes and a 13-ft-long panel bender, enabling us to seamlessly bend, form, and finish your laser-cut parts—all under one roof.

- Rapid Turnaround: In-house metal laser cutting and finishing enable faster delivery while maintaining consistent quality, helping you meet tight production schedules.

- Cost Efficiency: Minimize waste and reduce costs with our optimized laser cutting processes and expert material handling.

- Experienced Team: Benefit from our 60+ years of expertise, ensuring reliable and knowledgeable support from project start to finish.

Past Project Highlights

LMI has successfully partnered with OEMs across multiple industries, delivering custom laser cutting solutions that meet demanding specifications and tight schedules. Our expertise in CNC and fiber laser cutting enables us to handle intricate geometries, mixed materials, and high-volume sheet metal projects with repeatable precision.

Whether producing single prototypes or managing ongoing production, our team’s collaborative approach ensures reliable performance, faster lead times, and consistently excellent results.

Ready to Start Your Laser Cutting Project?

Partner with LMI Manufacturing for laser cutting excellence, exceptional quality, and dependable service

Laser Cutting Services Frequently Asked Questions

We accept SolidWorks, DWG, PDF, AutoCAD, and other standard CAD formats. Providing these files ensures accurate pricing and efficient programming for our CNC laser cutting systems.

Absolutely. Our team specializes in custom laser cutting solutions tailored to your exact needs. Whether it’s complex sheet metal laser cutting or high-precision components, we’ll work with you to ensure exceptional accuracy and finish.

Most laser cutting services are completed within 2–3 weeks, depending on complexity and volume. Our in-house capabilities and 6kW fiber laser cutting machine allow us to meet tight deadlines without compromising quality.

We cut stainless steel, aluminum, carbon steel, copper, and brass—handling material thicknesses up to 1 inch. Our advanced fiber laser cutting system ensures clean edges and precise results across all metals.

Yes. We support CNC laser cutting for single prototypes and repeat production runs. This flexibility allows OEMs to quickly move from design validation to full-scale manufacturing without delays.

Yes. Beyond metal laser cutting, we offer forming, machining, welding, and assembly — all in-house. This integrated approach keeps your entire production process streamlined and under one roof.

Fiber laser cutting provides faster speeds, higher precision, and better edge quality compared to traditional methods. Our 6kW laser cutting machine can handle both thin and thick metals with minimal heat distortion and superior finish.

We often help our customers lower their project costs. Our sheet metal laser cutting process minimizes waste and material use, while our in-house workflow reduces outsourcing costs, shipping delays, and inefficiencies — saving you time and money.

Yes. We reserve production capacity for urgent projects, allowing us to provide fast quotes and rapid turnaround on time-sensitive laser cutting jobs.