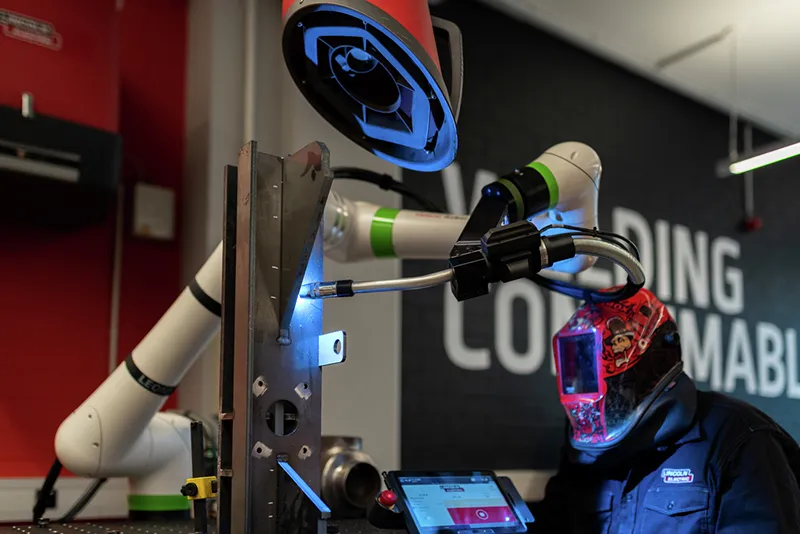

At LMI, we’ve added a Lincoln collaborative robot welder with a 72" reach to our welding department—and it’s already making a difference. The system takes on repetitive, heavy welds so our team can focus on higher-skill work like inspecting critical joints and handling tight, hard-to-hit features. The result: less physical strain for our welders and more consistent output for customers with mid- to high-volume demands.

Why a Cobot—and Why Now?

For structural applications, consistency isn’t optional. Large, load-bearing frames for critical-power equipment—such as battery backup trailers and generator support structures—are commonly governed by AWS D1.1. When a weld must carry heavy loads, you want repeatable bead placement, penetration, and fusion—every single part. A well-programmed cobot delivers that level of repeatability, part after part.

Technical Specs & Capabilities (at a glance)

- Reach & envelope: 72" reach to access larger weldments without constant re-clamping.

- Platform: Lincoln Electric collaborative welding cell (cobot-based) configured for MIG/GMAW; supports pulsed processes and flux-cored where appropriate.

- Power source & control: Industrial robotic power supply with advanced waveform control for arc stability, low spatter, and consistent penetration on carbon steel and stainless.

- Torch & wire: Compatible with common wire diameters (e.g., 0.035"–0.045") and both air- and water-cooled torch packages depending on duty cycle needs.

- Fixturing & positioners: Modular tooling and optional part positioners allow multi-face welding in one program to reduce handling time.

- Programming: Guided teach pendant plus offline programming for multi-pass paths, weave patterns, and repeatable travel speeds. Touch-sense and seam-finding options help maintain accuracy across batches.

- Quality & documentation: Stable programs, parameter lock-outs, and digital recordkeeping make it easier to produce consistent results and retain traceability for audits.

- Safety: Collaborative operation with integrated safety features and guarding tailored to the part and process.

What our team loves about it

- Reduced fatigue: The cobot handles the heavy, repetitive seams; operators load, unload, and oversee the cell.

- Skill, not substitution: Our welders still run the show—setting parameters, optimizing paths, and performing intricate hand welds robots can’t reach.

- Better time allocation: More time goes to inspection and small detail work where human judgment shines.

A realistic look at setup and throughput

- Programming & prove-out: The first time we run a new part, expect 2–3 sample iterations to perfect parameters and pathing.

- Ramp to production: Engineering and programming typically take about 4–6 weeks before a part is fully in production. Once set, the cobot accelerates output on volume runs.

- Right tool for the job: For very small quantities (e.g., ~15 parts), manual welding may be more efficient. Robotic welding pays off as volumes climb.

Why we chose Lincoln

Local support matters. Lincoln’s regional engineering team can come to our shop when needed, keeping uptime high and troubleshooting fast—so your schedules stay on track.

How this fits LMI’s broader strengths

Robotic welding builds on what LMI is known for: a deep bench of welding expertise and a commitment to consistent, reliable results. It complements our in-house forming, laser cutting, machining, assembly, and finishing coordination—helping us move from prototype to production with speed and control. Robotic welding is also a core differentiator for customers who need consistent quality across repeated runs.

Is your project a fit for our cobot cell?

You’ll benefit most if your parts:

- Have structural or repeatability-critical welds

- Run in mid- to high-volume quantities

- Would gain from consistent cycle times and quality documentation

Email your drawings (SolidWorks or STEP preferred), material specs, expected annual volumes, and any applicable weld standards. We’ll review for robot suitability, outline a prove-out plan, and map the fastest path to stable production.