LMI Manufacturing is growing again. This latest facility expansion adds a new, dedicated production area that gives our team more room to take on complex weldments, support high-volume welding, and streamline part flow across departments. With expanded space for production, inspection, and material movement, we’re strengthening what customers already value most about LMI: everything handled under one roof, delivered with the precision, reliability, and service our partners count on.

Why We Expanded Our Facility

The demand for reliable, high-quality metal fabrication continues to grow—especially for OEMs that rely on consistent production, repeatability, and faster turnaround times. To stay ahead of these needs, LMI expanded our facility to create a stronger, more efficient environment for every stage of production.

Here’s what drove the expansion:

- Increased OEM demand for mid- to high-volume runs

- Greater focus on high-volume welding, including robotic welding and grinding

- The need for a dedicated inspection and quarantine area, critical for quality assurance

- Faster quoting and prototyping expectations from customers

- A need to streamline part flow between laser cutting, forming, welding, machining, and assembly

- Long-term scalability, ensuring LMI can continue growing alongside our partners

This expansion is an investment in reliability, capacity, and performance—reinforcing our commitment to delivering consistent quality on every project.

A Look Inside the New Expansion

The new expansion area is purpose-built to support higher volumes, tighter quality control, and more efficient workflows. Based on the new layout and construction plans, this space adds targeted capabilities that directly improve production efficiency.

New Expansion Area

- A dedicated addition designed specifically for production growth

- Improved separation between work zones for better organization and safety

- Layout optimized for material flow, staging, and repeatable processes

Dedicated Inspection & Quarantine Area

- A clearly defined inspection area for verifying part quality

- Quarantine space for isolating nonconforming parts before they move downstream

- Added transparency and control for customers who require strict quality processes

This inspection capability is especially important for OEMs with quality-critical components, giving them added confidence in every shipment.

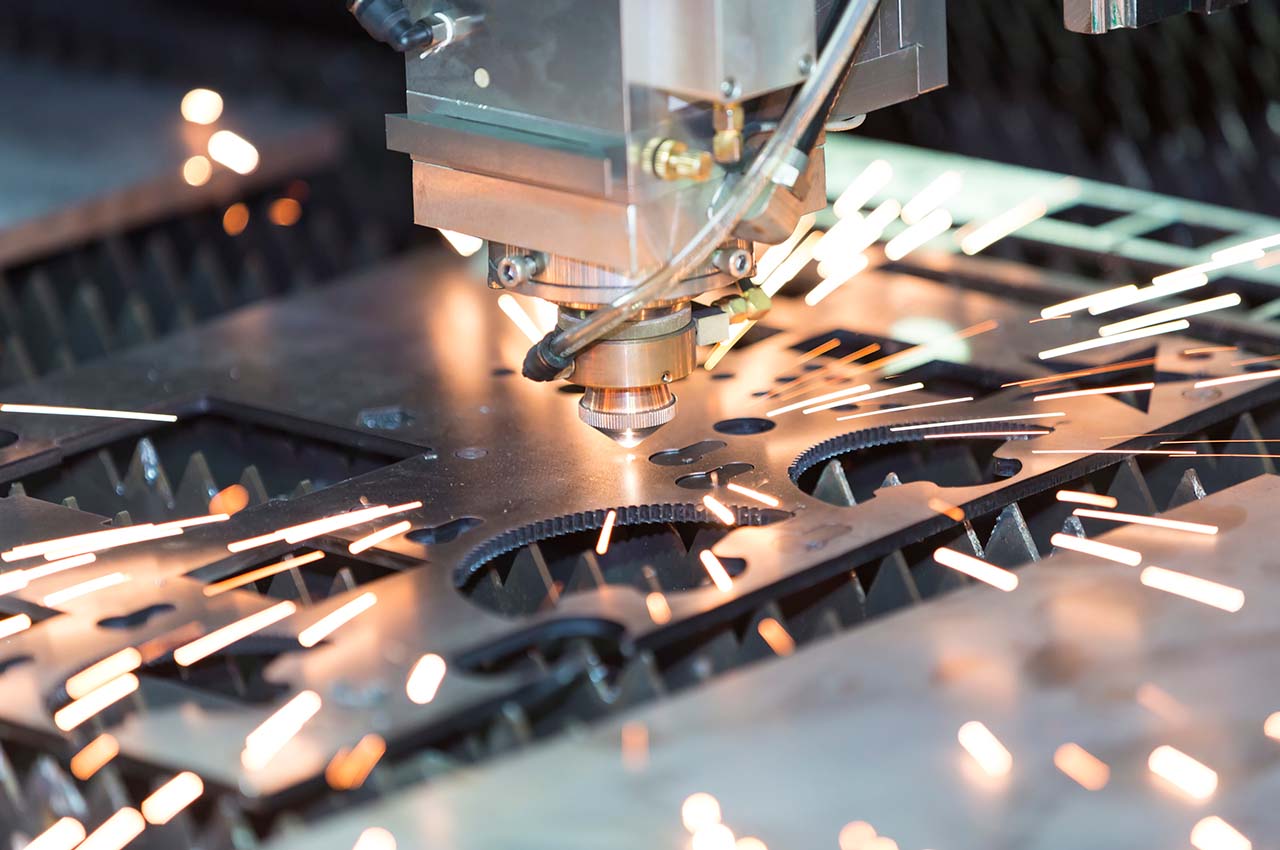

Robotic Welding & Grinding Stations

- Robotic welding cells designed for high-volume, repeatable weldments

- Dedicated grinding stations to support consistent finishing and throughput

- Improved consistency, efficiency, and scalability for welded assemblies

Together, these additions strengthen LMI’s ability to handle demanding production schedules without compromising quality.

What This Expansion Means for Our Customers

Our added space isn’t just a construction update—it directly improves how quickly and efficiently we can deliver high-quality parts. Here’s what the expansion means for the OEMs who rely on us:

Faster Lead Times

- More room for staging and movement reduces internal slowdowns

- Smoother transitions between cutting, forming, welding, machining, and assembly

- Increased capacity to run multiple jobs simultaneously

More Room for High-Volume Weldments

- Additional floor space dedicated to large, complex weldments

- Easier handling and maneuvering of multi-part assemblies

- Better organization of workstations, improving consistency and workflow speed

Stronger Prototyping-to-Production Support

- Expanded areas for setup, testing, and refinement

- Faster iteration cycles thanks to improved part flow

- Greater flexibility to introduce new parts without disrupting production

All Under One Roof — Now With Even More Capacity

- Laser cutting, forming, welding, machining, assembly, and finishing flow more efficiently

- Centralized processes reduce risk of delays and quality issues

- Larger footprint enhances our existing advantage: reliable fabrication with complete in-house control

Reinforcing Our Commitment to Quality & Efficiency

This expansion represents more than added space. It reinforces the standards that define how LMI partners with OEMs. Every improvement is designed to strengthen quality, consistency, and long-term reliability.

Greater Control Over Every Step

- Dedicated inspection and quarantine zones

- Safer, more organized workflows

- Improved layout supporting predictable, repeatable outcomes

Designed for Demanding Production

- Space built to support robotic welding and grinding

- Better handling of complex and high-volume weldments

- Infrastructure aligned with LMI’s pursuit of ISO certification

A Better Environment for Complex Work

- Additional space to handle intricate weldments and large assemblies

- More capacity for staging multiple jobs without sacrificing accuracy

- Enhanced support for projects that require advanced expertise and careful coordination

Continuous Improvement at the Core

- A facility designed around future automation and equipment upgrades

- Better alignment with LMI’s pursuit of ISO certification

- Stronger foundation for meeting growing customer demand with confidence

By expanding the facility, we’re doubling down on what customers value most: dependable quality, open communication, and the expertise to guide projects from concept to production.

What’s Next for LMI

Our expansion is just one step in a long-term plan to support OEMs with greater capacity, smarter workflows, and stronger technical expertise. As we continue building out the new space, we’re focused on improvements that directly benefit our customers and the industries we serve.

Investing in Talent

- Additional room creates opportunities to grow our welding, machining, and assembly teams

- More space for training and skill development

- Continued emphasis on expert craftsmanship and problem-solving

Scaling Welding & Automation

- Expanded support for robotic welding and finishing

- Facility layout ready for future automation investments

- Infrastructure designed to grow with customer demand

Supporting Long-Term Partnerships

- More predictable lead times

- Stronger quality controls

- A facility built to support repeatable, high-volume production

This next chapter at LMI is focused on smarter workflows, stronger quality assurance, and the same customer-first service that has guided us for decades.

Ready to see the difference an ISO-certified fabrication partner can make?

Let’s make something better - together.