OEM Fabricators — Sheet Metal Fabrication for OEMs

OEMs need a fabrication partner who can deliver consistent, production-ready components with the precision, reliability, and repeatability their products demand. At LMI Manufacturing, we support OEMs across a wide range of industries with high-quality sheet metal fabrication, tight-tolerance assemblies, and fully integrated production capabilities—all under one roof.

From prototypes to ongoing production runs, we provide the expertise, speed, and communication OEMs rely on to keep their operations moving. As an ISO 9001–certified manufacturer, LMI follows documented quality management systems designed to ensure consistency, accountability, and continuous improvement across every project.

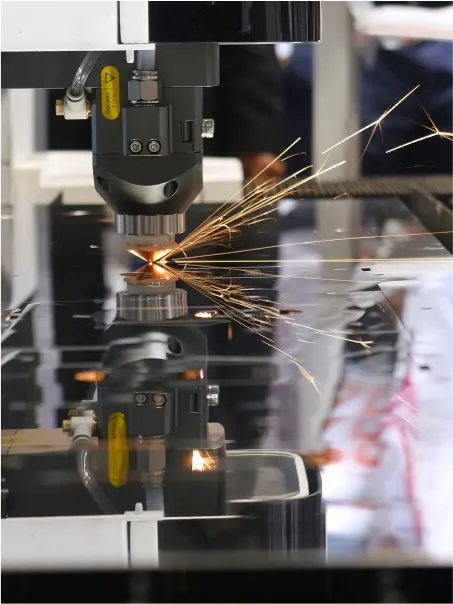

Precision Sheet Metal Fabrication for OEM Manufacturers

OEMs depend on fabrication partners who can produce consistent, repeatable parts at scale, without sacrificing accuracy or speed. At LMI Manufacturing, our vertically integrated production floor is built to deliver the tight-tolerance components and assemblies OEMs require to keep their products performing.

Whether you're building equipment, machinery, enclosures, or complete systems, we provide precision sheet metal fabrication backed by decades of experience and a commitment to reliable delivery.

We support OEMs that need:

- Production-ready parts with repeatable accuracy

- Tight-tolerance sheet metal fabrication for complex designs

- Welded assemblies engineered for strength and consistency

- Scalable manufacturing from prototype through full production

- Cost-efficient parts optimized for manufacturability

- Fast quoting and dependable lead times

- Clean communication and predictable scheduling

- A fabrication partner who prioritizes delivery reliability

Our team delivers consistent results across every process, helping OEMs reduce risk, streamline workflows, and maintain the quality their customers expect.

Components & Assemblies We Build for OEMs

OEM products rely on components that fit precisely, perform consistently, and integrate seamlessly into larger systems. LMI manufactures a wide range of production-ready sheet metal parts, welded assemblies, and custom subassemblies engineered to meet the performance standards OEMs require. From structural frames to precision brackets and enclosures, our team delivers parts that maintain quality across every run.

Structural & Frame Components

- Welded frames and bases

- Machine subframes

- Structural supports and reinforcement components

- Multi-part structural assemblies

Brackets, Mounts & Hardware

- Precision brackets and mounting plates

- Sensor, motor, and control mounts

- Support braces and alignment hardware

Enclosures & Housings

- Electrical enclosures

- Equipment housings and covers

- Control panel boxes

- Outdoor-rated or protective enclosures

Material Handling & System Components

- Conveyor frames and supports

- Custom trays, racks, and carriers

- Chutes, guides, and panels

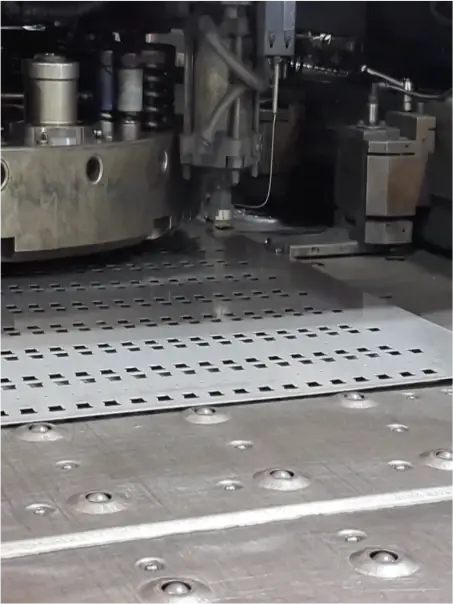

Precision-Fit Fabricated Parts

- Tight-tolerance sheet metal components

- CNC-machined features and formed parts

- Custom cut, punched, or bent components

OEM Subassemblies & Weldments

- Multi-component weldments

- Fully assembled units ready for integration

- Prototype assemblies that scale to production

With consistent results across all fabrication processes, we help OEMs maintain quality and reliability throughout their product lines.

All Under One Roof: Fabrication, Assembly & Finishing

OEMs need a fabrication partner who can deliver consistent quality at every stage of production. With nearly all processes housed under one roof, LMI maintains tight control over lead times, part consistency, and communication, helping OEMs reduce bottlenecks and streamline their supply chain.

Our experienced team and fully integrated workflows ensure your parts move efficiently from cutting to forming, welding, machining, assembly, and finishing.

Our in-house capabilities include:

By managing fabrication from start to finish, we help OEMs maintain reliability, reduce production variability, and achieve consistent performance across every build.

When Uptime Matters,

We Deliver Fast

OEMs operate on tight schedules, structured production cycles, and customer commitments that can’t slip. When a part is delayed, a design changes, or a production run scales unexpectedly, you need a fabrication partner who responds quickly and communicates clearly. At LMI, we combine smart quoting technology with efficient, in-house processes to reduce turnaround times and keep your production moving.

Fast quoting keeps your projects on schedule:

- Same-day or 24-hour quote acknowledgment

- Smart quoting system for fast, accurate pricing

- Two-business-day turnaround on quotes with SolidWorks files

- Clear communication so you always know what’s next

Reliable production keeps your line running:

- Rapid prototyping for design validation

- Consistent, repeatable quality across all runs

- Scalable capacity for mid-sized batches or long-term production

- In-house workflows that minimize handoffs and delays

Whether you’re launching a new product, updating an existing design, or managing steady production volumes, our team delivers the speed, consistency, and dependability OEMs rely on.

Why OEMs Trust LMI

OEMs need fabrication partners who can deliver consistent quality—every part, every batch, every time. That consistency is reinforced by LMI’s ISO 9001 certification, which formalizes our commitment to process control, traceability, and continuous improvement.

With decades of experience and a vertically integrated production floor, LMI provides the precision, reliability, and communication OEMs depend on to keep their products performing and their schedules on track

What sets LMI apart for OEMs:

- ISO 9001–certified quality management systems

- Repeatable quality across short runs and long-term production

- Tight-tolerance fabrication for complex or high-performance components

- Prototype-to-production support to accelerate product development

- Design-for-manufacturability guidance that reduces costs

- Reliable scheduling and lead times backed by clear communication

- Consistent results from fully integrated, in-house processes

- Ability to handle complex weldments and multi-part assemblies

We focus on being a proactive, dependable partner—helping OEMs reduce risk, strengthen product performance, and maintain a reliable, scalable supply chain.

Right-Sized for Your OEM Needs

Every OEM operates differently. Some need complex weldments and large assemblies, while others require small, high-precision components delivered consistently over long-term production cycles. LMI is structured to support both ends of the spectrum, offering the flexibility, responsiveness, and process control OEMs need to stay competitive.

We’re a strong fit for OEMs that need:

- Reliable production support for long-term or repeat orders

- Complex assemblies and welded structures built with precision

- Tight-tolerance sheet metal parts engineered for consistent performance

- Non-standard materials or specialty requirements

- Scalable fabrication from prototype to full production

- A responsive team that adapts quickly to design updates or schedule changes

Our goal is to provide a seamless partnership, delivering the quality, speed, and consistency OEMs expect while supporting their growth and evolving product needs.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.