Metal Fabrication Services for the Material Handling Industry

Fabrication Built for Material Movement

LMI Manufacturing is a trusted partner for OEMs that drive the material handling and logistics industries. Our precision-fabricated components power systems found in high-throughput operations across the country—including fulfillment centers, distribution hubs, retail backrooms, and industrial warehouses.

From welded brake assemblies to formed and coated safety parts, we provide the expertise and capabilities needed to keep complex equipment moving—safely and reliably.

Proven Fabrication Partner for OEMs in Logistics & Material Handling

The components we fabricate are found in applications at some of the most recognized logistics and retail organizations. Our customers include nationally and internationally known OEMs whose products are integral to the operation of major facilities like Amazon, UPS, FedEx, and Walmart.

Our fabrication supports:

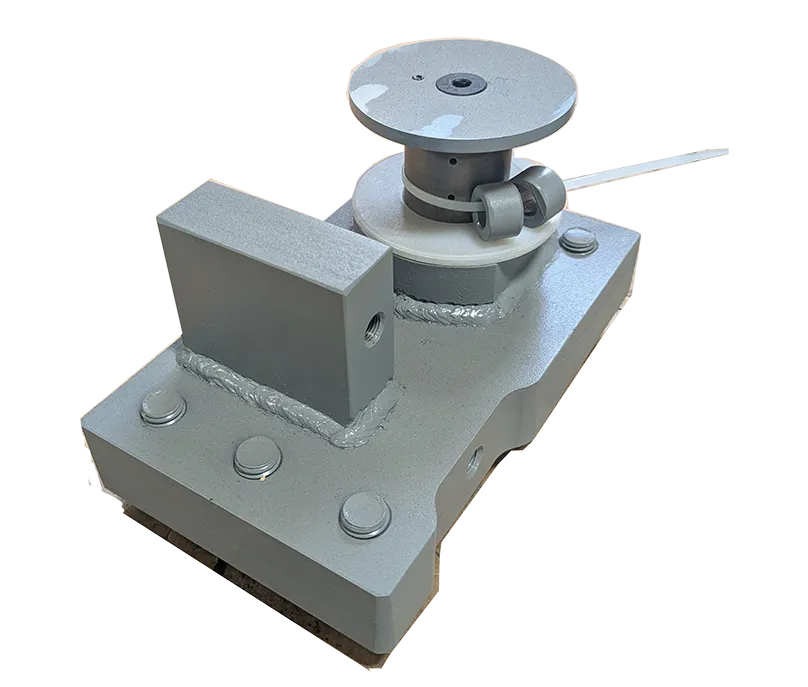

- Brake components and safety cams for vertical lift systems

- Structural parts for vertical reciprocating conveyor (VRC) assemblies

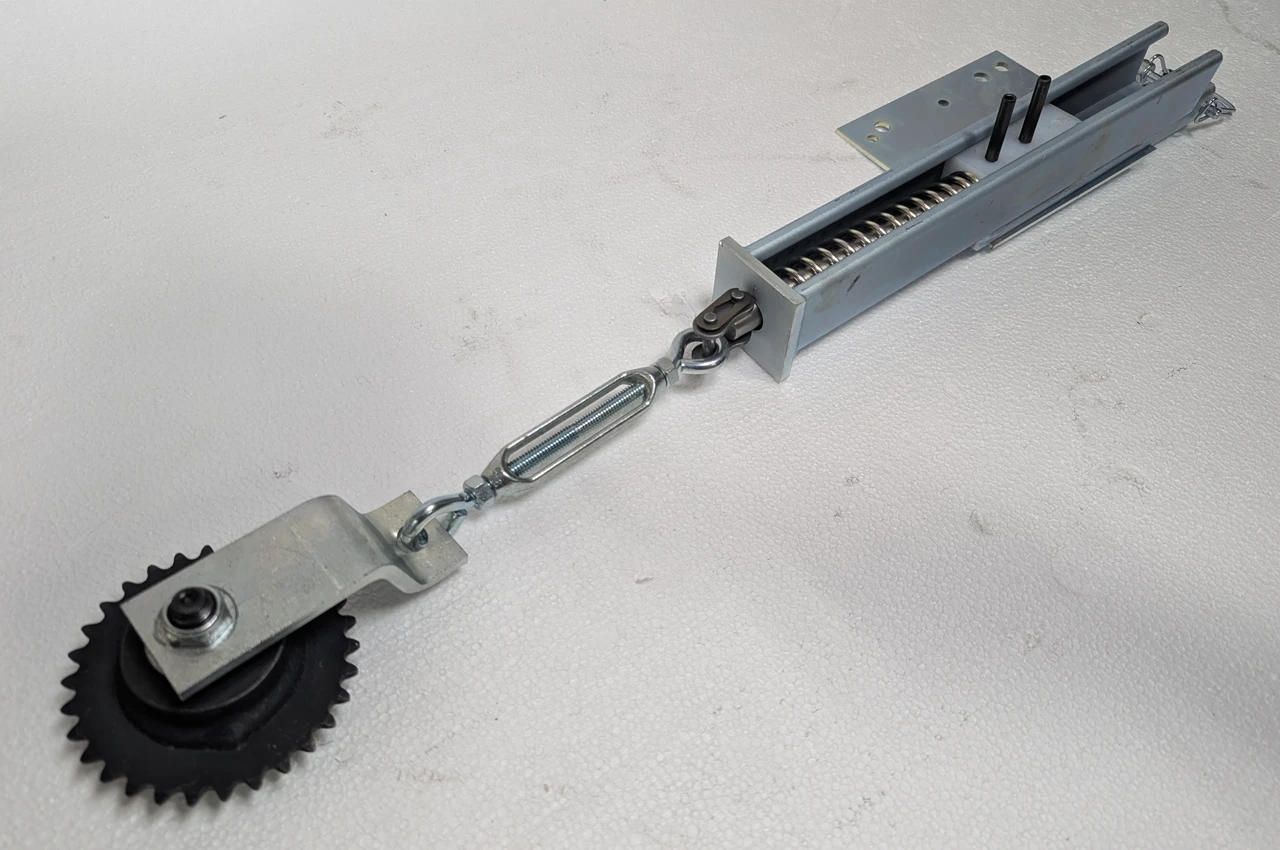

- Chain tensioners and welded steel subcomponents

- Custom and standard parts for new builds and service replacement lines

With over 60 years of experience, we know what it takes to deliver quality fabrications that meet the demands of high-volume, safety-critical environments.

From Simple Parts to Complex Multi-Process Assemblies

At LMI, we handle a wide range of part complexities—from straightforward laser/formed brackets to fully assembled, coated, and heat-treated weldments. Our internal work centers are optimized to meet every requirement of the material movement space.

Our capabilities include:

- Laser cutting

- Press brake forming

- Robotic and manual welding

- Machining and milling

- Heat treating

- Wet paint or powder coating (outsourced locally)

- Mechanical assembly

This full-spectrum service allows us to streamline production and keep control over quality and lead times from start to finish.

Built for Both Standard and Custom Fabrication

We excel in environments that demand both consistency and flexibility. Many of our OEM partners manufacture standard products but require slight customization from project to project. Our ability to adapt to custom specifications—while maintaining the discipline and efficiency of standard part production—is what sets us apart.

Common materials include:

- Carbon steel with protective coatings

- Stainless steel for corrosion-resistant applications

Whether your project involves a single SKU with recurring demand or a suite of slightly varied assemblies, LMI has the agility and tooling to deliver.

Fast Quotes. Reliable Delivery. Consistent Quality.

One of the most common challenges our material handling clients face is urgency. Tight installation deadlines demand that suppliers be responsive, proactive, and dependable. That’s where we shine.

LMI is recognized for:

- Rapid quote turnaround—often within 2 business days

- Shorter production cycles

- Clear and responsive communication

- Strong quality control and formalized non-conformance tracking

Customers routinely name LMI among their most consistent and communicative suppliers—a testament to our team’s focus on service and reliability.

Mid-Volume Production Is Our Sweet Spot

We specialize in mid-volume production runs and repeat jobs where consistency, cost-efficiency, and adaptability are key.

We work best with OEMs that:

- Provide estimated annual usage volumes (EAUs)

- Require repeat monthly orders across SKUs

- Seek consistency in part delivery, even when specs vary slightly

We analyze each job to determine the most efficient path—from laser runtimes to press brake programming and welding strategy. Our experience in both robotic and manual welding allows us to match the right approach to every assembly.

While we don’t take on one-time-only jobs, we welcome ongoing orders—even if parts change slightly over time.

Support from Prototype to Ramp-Up

Our team often gets involved in the earliest stages of product development. From initial pricing to final production, we take time to understand the use case, volume requirements, deadlines, and design details. If a part isn’t manufacturable as designed, we’ll let you know—offering honest feedback and a path forward.

We evaluate each project based on:

- Intended application

- Required schedule

- Labor hours needed

- In-house capability match

If we can’t take it on, we’ll tell you. But more often than not, we can—and we do.

Built to Move With You

We’re proud to support OEMs in the material movement industry with the parts that keep your systems rolling. Whether it's a safety-critical brake component or a series of welded and coated assemblies, LMI provides the consistency, speed, and communication your operation depends on.

Let’s talk about your next project and see how LMI can keep your production moving forward.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.