Metal Fabrication for the Food Processing Industry

Precision Fabrication for the Systems That Keep Food Moving

The products we make are a part of your food supply chain.

If you’ve eaten food, bought soda, or went to a national fast food chain in the United States in the past 40 years, there is a very strong possibility that LMI contributed to the supply chain that supports your unhealthy eating habits.

At LMI Manufacturing, we’ve been supporting the food processing industry for over 40 years with fabricated components that are durable, sanitary, and built to exacting standards. Whether it’s forming stainless steel egg molds, welding enclosures for sealing machines, or delivering urgent replacements for bottling systems, we understand what it takes to keep food production lines running

Provide us with your deburring and finishing specs to ensure we meet your products' quality standards for your applications. We work with a handful of vetted 3rd parties to ensure passivation or other finishing processes such as mirror polish finishing are attained for your project.

Our deep experience with stainless steel, quick-turn support, and repeat OEM component fabrication makes us a reliable partner for food processing equipment manufacturers across the country.

OEM-Trusted Fabrication for Sanitary, High-Volume Environments

LMI supports the fabrication needs of OEMs whose products power production lines in bottling plants, prepared food facilities, dairy operations, and more. You’ll find our parts in applications like:

- Beverage and yogurt pouch lines

- Egg cooking and packaging systems

- Conveyor handling systems for cans and cartons

- Government food supply operations

- Cheese and deli meat slicing and packaging lines

We’ve earned a niche in this industry by consistently producing parts that meet hygiene standards and function flawlessly in high-speed, high-washdown environments.

Repeat OEM Components, Custom Parts & Replacement Fabrications

From first samples to full production, we fabricate repeat OEM parts and custom components to meet your specs. Common parts we fabricate include:

- Stainless steel egg molds and trays

- Cosmetic guards, panels, and safety shields

- Enclosures and plenums for sealing and processing machines

- Framework for packaging, labeling, and palletizing equipment

- Enclosures for irrigation and water pump systems

- Emergency-use replacement parts for food lines that can’t afford downtime

Whether it’s a sample run or long-term production, we bring consistency, clarity, and speed to the table.

Clean Welds, Smooth Finishes, and Trusted Sanitary Fabrication

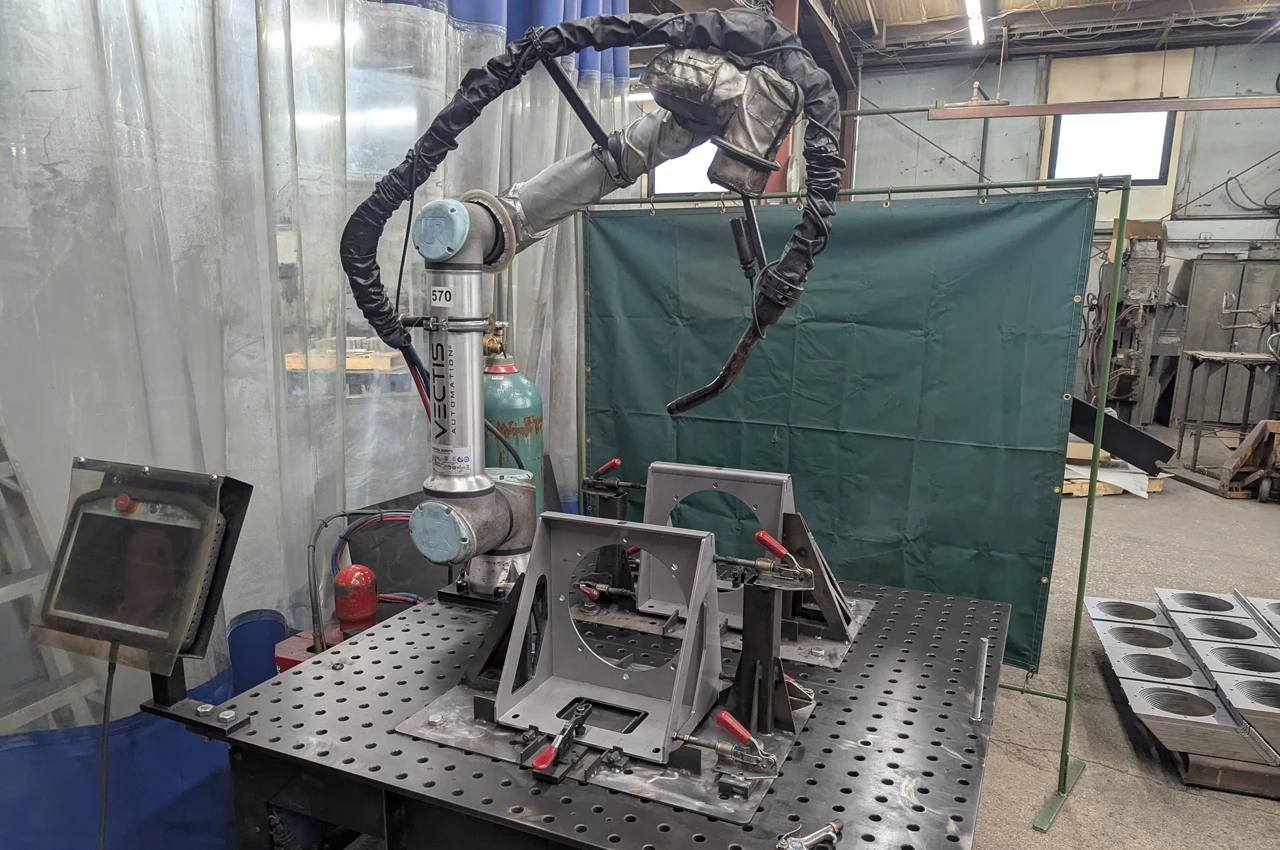

Food processing fabrication demands more than just strength—it demands clean, sanitary welds, tight fit ups, and carefully considered finishes. LMI has decades of experience working with 304 and 316 stainless steel in ways that meet both structural and hygiene needs.

We specialize in:

- Smooth welds with minimal distortion or porosity

- Punching, forming, and grinding of stainless steel

- Surface finishes optimized for food-safe environments

Our fabrication practices ensure your equipment performs—and cleans—exactly as expected.

When Uptime Matters, We Deliver Fast

Many of our food processing clients come to us when speed is non-negotiable. We’re used to working with OEMs who need acknowledgment and quotes turned around immediately, and parts delivered in two to three weeks.

At LMI, we deliver:

- Same-day PO acknowledgment and rapid requotes

- Lead times aligned to your production windows

- Repeatable results for standard or custom parts

- Flexibility to jump in when other suppliers fall short

We’ve built our reputation on keeping up with the demands of food production lines—and keeping our promises.

Trusted for Sanitary Environments, Tight Tolerances, and High Stakes

From emergency replacements to overflow work and new product builds, LMI supports food processing OEMs with consistent weld quality, predictable turnaround, and collaborative service. We understand what’s at stake when your equipment is responsible for moving, sealing, cooking, or packaging food.

What sets LMI apart:

- Experience working in stainless-heavy environments

- Ability to take on small-to-mid volume runs and recurring projects

- Fabrication of complex weldments that integrate seamlessly into OEM assemblies

- In-house control over quality from laser to weld to assembly

- Long-term relationships built on transparency, results and frequent reviews

Precision Fabrication for Every Stage of Food Processing

Whether you’re building machines that cook, convey, seal, or slice—LMI has the fabrication experience and responsiveness to support your success. Let’s work together to move your next food processing project forward.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.