Metal Fabrication Services for the Electrical & Power Generator Industries

Expert Fabrication. Reliable Performance. Built for Electrical OEMs.

LMI Manufacturing delivers precision metal fabrication services to support the electrical industry’s most complex and demanding assemblies. From dry-type transformer enclosures to copper coils and structural weldments, our team is trusted by leading OEMs to produce high-quality components that perform under pressure.

We understand the needs of electrical equipment manufacturers—tight tolerances, reliable turnaround times, and flexibility from prototype to scale. Our in-house capabilities, advanced machinery, and experienced team ensure your parts are built right the first time.

Built for Power:

Components We Fabricate

Our metal fabrication services support a wide range of electrical applications, including commercial construction, data centers, industrial facilities, and utility systems.

Typical components we produce include:

- Custom steel or aluminum enclosures (dry-type and wet-type)

- Large structural enclosures (up to 12' x 12' x 12')

- Copper coils and copper lugs

- Multi-part welded assemblies with complex geometries

- Small to mid-sized electrical enclosures (as small as 1' x 1')

- Large panels for outdoor enclosures. We cut galvanized, pre-painted

Whether your product is heading into a transformer system, a capacitor switching assembly, or a power distribution cabinet, we’ll help you meet exacting specifications with ease.

All Under One Roof – Fabrication, Assembly & Finishing

We don’t just cut and weld. At LMI, we provide full-service metal fabrication with an emphasis on quality, speed, and cost control.

Our In-House Capabilities Include:

- Laser Cutting – 6kW fiber laser with a large-format bed (79" x 158")

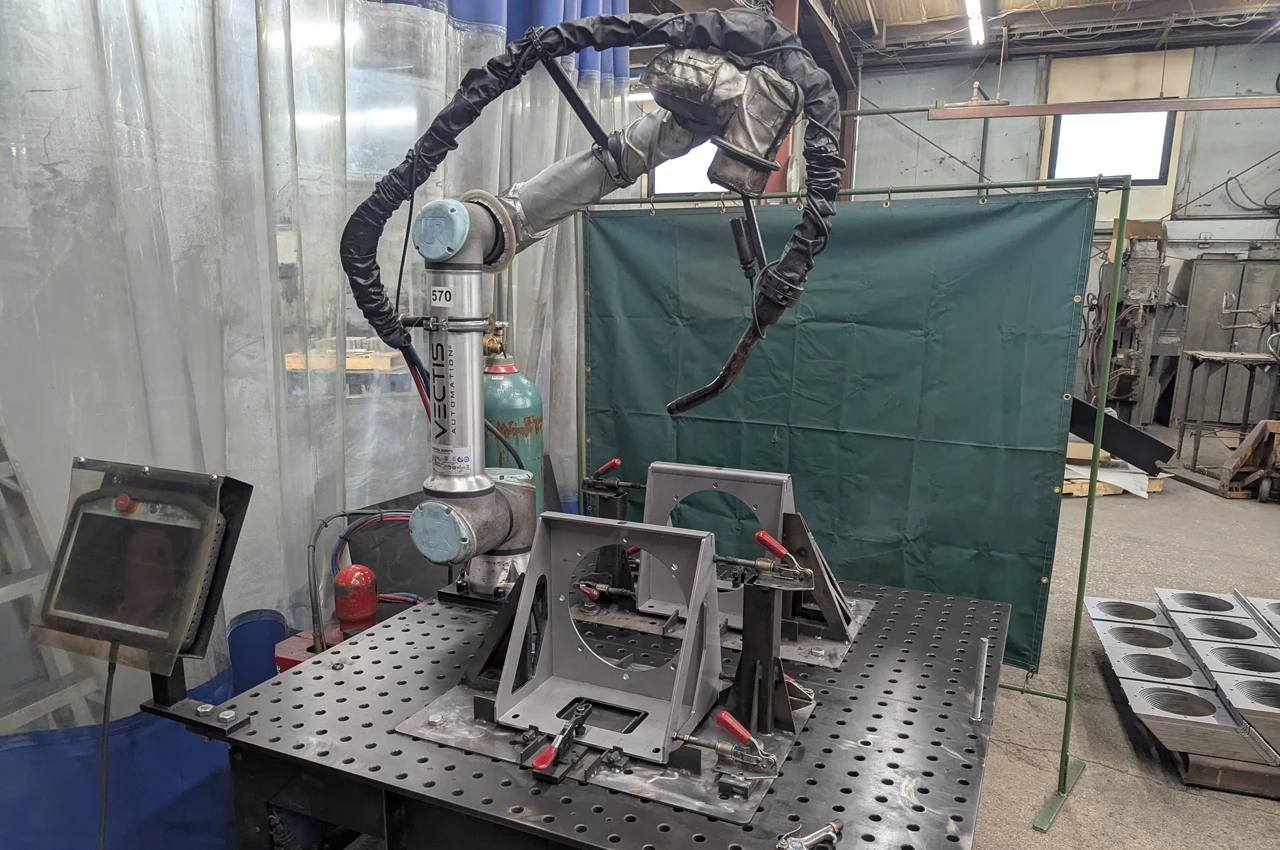

- Welding (Robotic & Manual) – Certified up to 1" thick welds

- Machining, Grinding & Sawing

- Turret Punching – Extensive tool library (1,000+ tools)

- Press Brake Forming – Broad range of tooling for precise bends

- Tube Bending & Roll Forming – For structural support and unique shapes

- Assembly Services – Complete or partial subassembly integration

- Finishing – Local powder coating partner ensures fast turnaround & cost savings

Our vertically integrated operation streamlines production, reduces lead times, and ensures higher consistency across every project.

Electrical Industry Expertise

You Can Trust

For over 60 years, we’ve partnered with nationally and internationally recognized electrical OEMs to supply components that meet the highest standards.

Why manufacturers in the electrical space trust LMI:

- Complicated Weldments – We routinely deliver multi-component assemblies with tight tolerances and consistent weld quality.

- Design Support – Don’t have a full blueprint? No problem. Our team can help optimize your part or enclosure for performance and manufacturability.

- Prototyping to Production – We help you develop smarter, faster, and more cost-effective solutions.

- Speedy Quotes – Send us your SolidWorks file and we’ll deliver a quote within 2 business days if the material and processes are standard.

Need to improve an existing product? We’ve helped OEMs resolve quality issues, reduce lead times by up to five weeks, and achieve better weld consistency with automated processes.

Right-Sized for Your needs

We’re a strong fit for projects involving:

- Large assemblies and weldments

- Non-standard materials or finishes

- Complicated fabrication or assembly processes

- Tailored part solutions that require expertise and agility

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.