Metal Fabrication for the Agriculture Industry

Agriculture depends on equipment that works hard every day, often in harsh outdoor environments. In fact, agriculture is where LMI Manufacturing got its start, building parts for farmers long before advanced fabrication technology became the industry standard.

Today, we support agriculture OEMs, farm equipment builders, material handling manufacturers, and ag-tech innovators with durable, precision-built metal components that stand up to real-world use.

From welded frames and hydraulic brackets to auger housings, conveyor assemblies, and outdoor-rated enclosures, our in-house capabilities help ensure your equipment performs reliably in the field and across your production lines. Backed by decades of expertise, fast quoting, and consistent quality, we’re here to help you keep your operation moving forward.

Precision Fabrication for the

Equipment That Feeds the World

Agricultural equipment needs to perform under constant stress: vibration, impact, weather exposure, washdowns, and heavy-duty workloads. That’s why OEMs rely on fabrication partners who understand the unique demands of the field. At LMI Manufacturing, we build components and assemblies engineered for durability, strength, and long-term reliability.

Whether you need welded frames for harvesting equipment, brackets for hydraulic systems, or corrosion-resistant assemblies for crop handling lines, our team delivers parts that meet tight tolerances and arrive ready for real-world use.

We support agriculture manufacturers that need:

- Reliable components for tractors, harvesters, and farm machinery

- Corrosion-resistant parts for outdoor and washdown environments

- Heavy-duty weldments for high-impact or high-vibration applications

- Precision-formed and machined components for critical moving systems

- Durable metal assemblies that withstand long-term field use

- Rapid turnaround on prototypes and production-ready parts

- Consistent quality across multi-process builds

- A dependable partner who keeps uptime and lead times a priority

With a vertically integrated operation, experienced welders, and an in-house forming and machining department, we deliver the consistency agriculture manufacturers expect at every stage, from prototype to production.

Built for the Field – Components We Fabricate

Agriculture equipment runs in demanding environments, which means every component needs to be engineered for strength, reliability, and long-term performance. LMI fabricates a wide range of agriculture-ready parts and assemblies built to handle heavy loads, constant motion, and exposure to the elements.

From welded frames and protective guards to conveyor components and hydraulic brackets, our team delivers production-ready parts that help keep your equipment running when uptime matters most.

Structural & Frame Components

- Heavy-duty welded frames

- Machine bases and subframes

- Loader, tractor, and harvester brackets

- Structural supports for crop processing equipment

Wear & Protection Components

- Abrasion-resistant plates

- Equipment guards and shielding

- Protective housings and covers

- Outdoor-rated metal enclosures

Material Handling Components

- Conveyor frames for wash, sort, and pack lines

- Chutes, hoppers, and auger housings

- Stainless steel components for food-grade applications

- Roller and belt conveyor supports

Mechanical & Hydraulic System Components

- Pump brackets and mounting plates

- Hydraulic system brackets and reservoirs

- Formed tubes and fluid-handling components

Grain, Seed & Storage Equipment Parts

- Bin stiffeners and supports

- Structural parts for seed and grain handling systems

Ag-Tech & Precision Farming Components

- Sensor and control system brackets

- Enclosures for GPS, IoT, and autonomous equipment

No matter the complexity or production volume, our team delivers consistent results backed by decades of metal fabrication experience.

All Under One Roof — Fabrication, Assembly & Finishing

Agriculture manufacturers work with tight production schedules, seasonal demand spikes, and equipment that must hold up under constant stress. That’s why partnering with a fabrication supplier who does everything under one roof creates a real advantage.

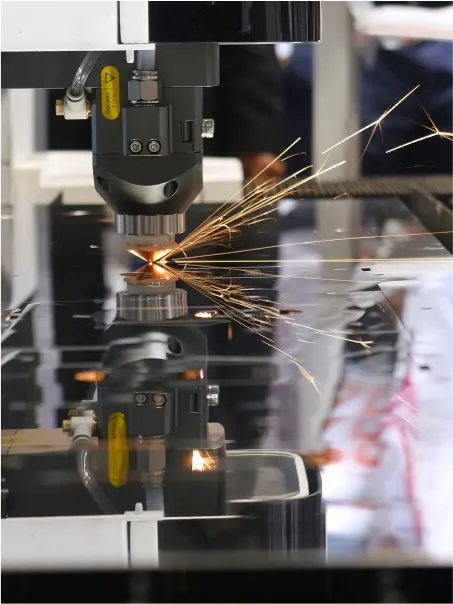

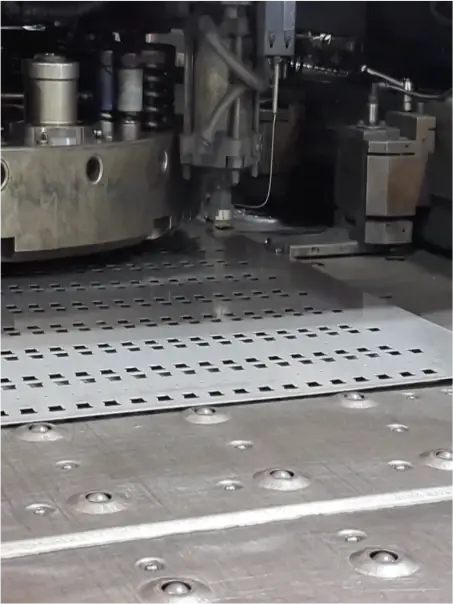

At LMI Manufacturing, our integrated production floor delivers consistent quality across every process: cutting, forming, welding, machining, assembly, and finishing. This way, your parts move smoothly from one stage to the next without delays or guesswork.

Our in-house capabilities include:

Note from Amy: when we build this, let’s use the same layout we have on the Metal Fab Services page:

By keeping nearly every step of production in-house, we help agriculture OEMs reduce lead times, maintain part consistency, and gain a transparent partner they can count on from prototype through full production.

When Uptime Matters, We Deliver Fast

In agriculture, downtime isn’t just inconvenient — it’s costly. When equipment goes down during planting, harvesting, or production cycles, every hour matters. That’s why agriculture manufacturers rely on partners who respond quickly, quote accurately, and deliver parts on time. LMI combines advanced quoting technology, streamlined workflows, and a highly experienced team to help keep your operation moving without interruptions.

Fast turnaround begins with fast quoting:

- Same-day or 24-hour quote acknowledgment

- Smart quoting technology for accurate pricing

- Two-business-day turnaround on quotes with SolidWorks files

- Clear communication so you always know where your project stands

And continues with dependable production performance:

- Rapid prototyping for testing and validation

- Consistent weld quality for heavy-use assemblies

- Reliable repeatability for long-term production runs

- In-house processes that reduce handoffs and delays

Whether you’re improving an existing design, replacing a critical component, or ramping up production, our team responds quickly so you can maintain uptime across your equipment and operations.

Why Agriculture Manufacturers Trust LMI

Agriculture equipment manufacturers need a fabrication partner who delivers consistency, strength, and reliability at every stage of production. That expectation aligns with how LMI began—supporting farmers with practical, hard-working parts designed for real field conditions.

With decades of experience and a fully integrated facility, LMI provides the technical expertise and responsive support agriculture OEMs count on to keep equipment performing in the field and throughout the production process.

That agricultural foundation still shapes how we approach fabrication today: practical design input, durable weldments, and parts built to perform under pressure—not just look good on paper.

What sets LMI apart for agriculture:

- Expert weldments for heavy-duty, high-vibration equipment

- Tight-tolerance parts that perform reliably under constant stress

- Prototype-to-production support for continuous equipment improvement

- Design-for-manufacturability guidance that reduces cost and strengthens performance

- Reliable lead times and transparent communication from quoting to delivery

- Consistent quality across multi-process builds handled entirely in-house

- Ability to take on complex weldments and large assemblies others avoid

From seasonal timelines to uptime requirements, our team understands the operational pressures agriculture manufacturers face and we bring the experience, responsiveness, and craftsmanship needed to help you stay ahead.

Right-Sized for Your Needs

Every agriculture manufacturer has different demands — from large welded assemblies and structural components to small, high-precision parts needed for advanced equipment or ag-tech systems. LMI is built to support projects of varying size and complexity while maintaining the flexibility, communication, and collaboration you expect from a trusted partner.

We’re a strong fit for agriculture manufacturers that need:

- Large assemblies and complex weldments built to withstand field conditions

- Non-standard materials or corrosion-resistant finishes for outdoor use

- Custom brackets, frames, and structural components for heavy-duty equipment

- Intricate fabrication and assembly processes managed under one roof

- Prototype development that transitions smoothly into production

- A responsive team that adapts quickly to timeline changes and seasonal demand

Our approach keeps your priorities at the center: reliable quality, dependable timelines, and a collaborative partnership that supports your equipment and your long-term production goals.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.