Our Capabilities

Comprehesive Metal Fabrication

At LMI Manufacturing, our comprehensive capabilities encompass a wide array of precision metal fabrication services designed to deliver exceptional quality and performance. Our in-house processes ensure that every aspect of your project meets your specific requirements, timelines, and budgets.

Fabrication Services Overview

Laser Cutting

Precision cutting with our advanced 6 KW fiber laser.

Sheet Metal Punching

Cost-efficient and accurate sheet metal processing.

Sheet Metal Forming

Precise forming capabilities tailored for each project.

Roll Forming

Consistent, high-quality production for uniform profiles.

Tube Bending

Accurate bends for precise, complex geometries.

Welding & Grinding

Certified welders delivering robust and reliable weldments.

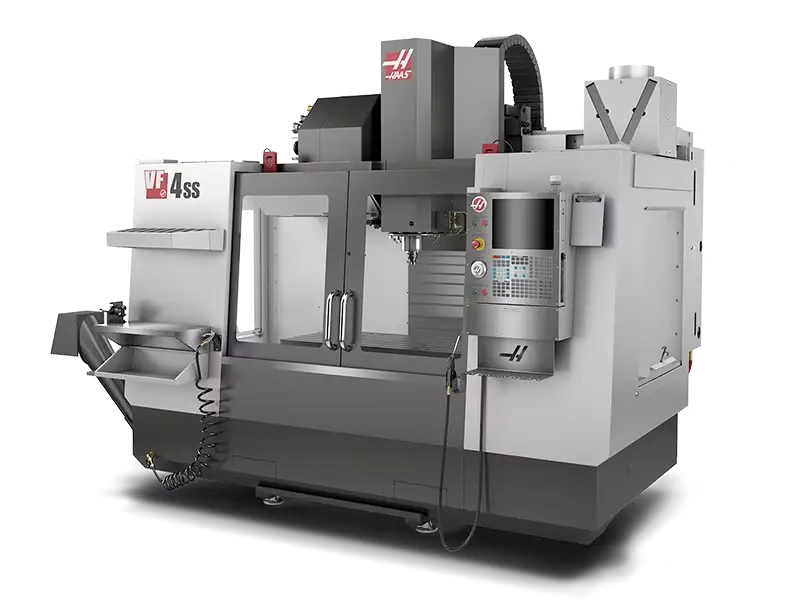

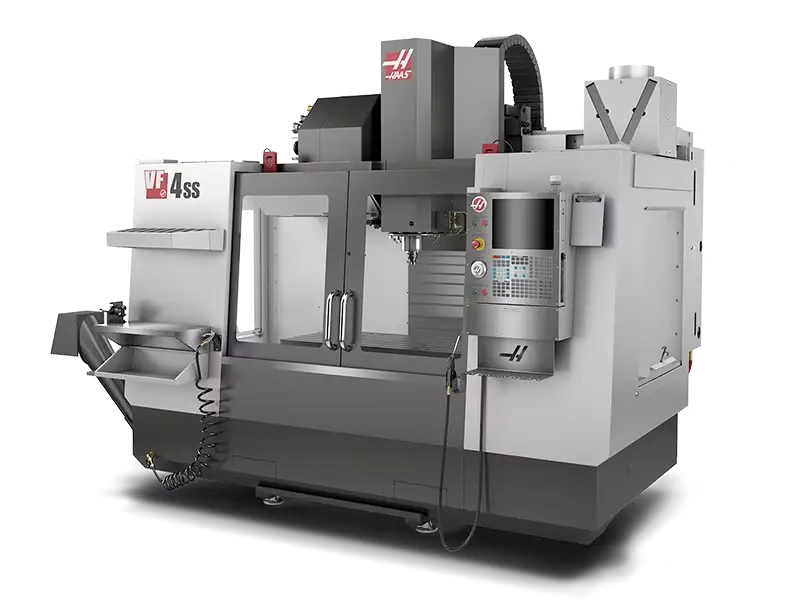

Machining

High-precision CNC machining for intricate and detailed components.

Sawing

Accurate metal cutting services for a variety of materials.

Assembly

Complete, reliable assembly solutions managed entirely in-house.

Finishing & Powder Coating

Premium finishes coordinated seamlessly with our trusted local partners.

Metal Fabrication Technical Specifications

- Max. Sheet Size (X, Y): 158" x 79”

- Max. Axis Travel (X, Y, Z): 160" x 81" x 4"

- Max. Axis Positioning Speed (X, Y): 4,724"/min per axis

- Max. Z-Axis Speed: 2,362"/min

- Repeatability (Tolerance): 0.0004"

- Max. Sheet Size (X, Y): 100" x 39"

- Max. Axis Travel (X, Y): 39" x 50"

- Table Speed (X, Y combined): 1,968"/min

- Turret Stations: 58

- Turret Rotation per Min: 30 RPM

- Stroke per Min: 350/min

- Hits per Min: (1" Centers) 200 Hpm

- Capacity (t.): 28 – 350 ton

- Overall Die Surface (ft.): 10' – 12'

- Stroke Length (in.): 8"

- Open Height (in.): 15"

- Press Speed: 80 cycles/min

- Tolerance (±): 0.005 in

- Max bed length (ft): 6’

- Material thickness (in.): (.312) 5/16" max thickness

- Roll Diameter: 8"

- Table Size: 52.0" x 19.5"

- Travels (XYZ): 50" x 20" x 25"

- Spindle Speeds: 100 to 12000 RPM

- Rapid Traverse (XYZ): 1400 IPM

- Max Cutting: 833 IPM

- Table Size: 73" x 24"

- Travels (XYZ): 60" x 30" x 28"

- Spindle Speeds: 100 to 8000 RPM

- Rapid Traverse (XYZ): 500 IPM

- Table Size: 40" x 19"

- Travel (XYZ): 50" x 20" x 25"

- Spindle Nose to Table: 4" – 29"

- Rapid Traverse Rates: 710 IPM

- Spindle Speed: 0 – 7,500 RPM

- Travel (XZ): 8.45" x 20"

- Rapid Traverse (XZ): 710IPM

- Spindle Bore: 3.02"

- Spindle Speeds: 50 – 3400 RPM

- Max Turning Diameter: 10"

- Max Turning Length: 20"

- Max Bar Capacity: 2"

- Swing Over Bed: 23"

Welding Solutions

- MIG (Metal Inert Gas)

- TIG (Tungsten Inert Gas)

- Robotic

- Stud Welding

- Solder and Brazing

Batch Paint Booth Finishes We Work With:

- Any kind of enamels

- Catalyst paints

- Two-part epoxy paints

- Two-part polyurethane paints

- Capacity – In Mild Steel: .250" / 1/4"

- Shear Length: 144"

- Rake of Upper Blade: 1/4"

- Speed: 60 PM

- Working Height: 38"

- Number of Hold Downs: 13

- Gap – Throat: 18"

Industries We Serve

We serve a diverse array of industries, including:

Data Centers

Construction &

Agriculture

Food Processing

Electrical Cabinets

Medical Cabinets

Industrial

Machinery

Why Choose LMI Manufacturing?

- Decades of Expertise: Over 60 years in precision fabrication, delivering unmatched quality and service.

- End-to-End Capabilities: All fabrication processes handled in-house, ensuring quality control and faster project completion.

- Competitive, Transparent Pricing: Clearly outlined pricing with no hidden costs.

- Collaborative Service: We partner closely with clients, offering tailored solutions to meet unique challenges.

Ready to Start Your Project?

Experience the full range of LMI Manufacturing’s capabilities and see why we’re trusted nationwide.