Quality and Certifications

Uncompromising Quality. Trusted Expertise.

At LMI we understand the importance of consistently making your parts to spec and within tolerance. From first sample to high production runs, quality & tracking is a critical part to our and your manufacturing process. Whether you’re a leading OEM or an engineer searching for a reliable manufacturing partner, you can count on LMI to meet your exacting standards with precision, transparency, and reliability.

Why Choose LMI for Quality Metal Fabrication?

AWS Certified Welders

Qualified up to 1" thick welds with WPS’s

ISO 9001-Certified Quality System

Third-party audited processes and continuous improvement practices ensure your most demanding projects meet exacting standards—delivered with consistency and reliability.

Advanced Technology

QT9 Quality Software, Part Tracking ID Systems, and Capacity Planning Tools ensure traceability, accountability, on-time delivery, and efficiency.

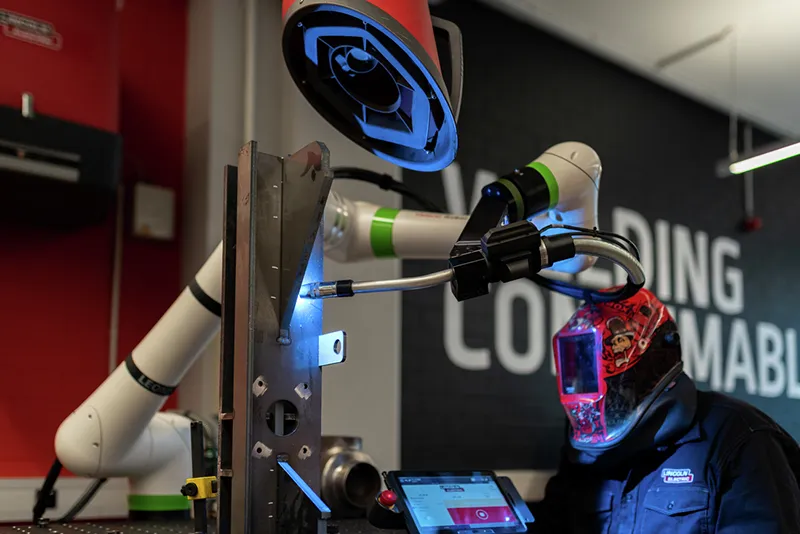

Robotic Welding & Precision Fabrication

Robotic arms deliver consistent, high-tolerance welds that outperform traditional hand-welding methods.

Full In-House Fabrication and Machining Capabilities

From laser cutting to assembly — everything happens under one roof for better quality control.

Trusted by Leading OEMs

Built to meet the strict standards of Fortune 500 manufacturing OEMs

Working with us means fewer emails, fewer

issues, and fewer delays.

Quality Systems Built for OEM Demands

We understand that major OEMs have rigorous quality control processes. That’s why companies trust LMI for their fabricating needs. LMI has invested heavily in both technology and expertise to deliver repeatable, audit-ready manufacturing results:

- QT9 Quality Management Software: Tracks quality processes, policies, equipment calibrations, corrective actions, and more.

- Third-Party Audited and ISO-9001 Compliance: We operate under a practical, reliable, quality management system where OEM customers are invited to audit our systems directly.

- Production Traceability: Our Part Tracking ID System ensures complete traceability from raw material to finished assembly. Heat lots and material tracking are common.

- Capacity Planning Technology: Helps us proactively manage schedules, resources, and output for your project’s success to ensure on-time delivery.

Certifications & Standards

- AWS D1.1 Certification Compliance: Our welders meet the standards set by the American Welding Society (AWS), ensuring strength, durability, and precision.

- ISO 9001:2015 Certified: We meet rigorous qualifications for processes throughout our shop.

- Third-Party Welding Engineer Oversight: Ensures our WPS (Welding Procedure Specifications) and WPQ (Welder Performance Qualifications) meet and exceed standards.

- Calibrated Equipment: Welding machines and inspection tools are annually calibrated and verified by manufacturers for optimal performance

How We Deliver Quality in Every Part

At LMI, quality is a process, not just a promise. Here's how we ensure excellence:

- Work Instructions and Redundancy Plans: Every complex weldment or assembly follows documented work instructions with production backup plans for consistency.

- Corrective Action Tracking: If an issue arises, it’s addressed systematically, documented, and resolved within our quality management software.

- Supplier Certifications: We manage and verify heat certifications and lot traceability for raw materials to ensure integrity from the ground up.

Why LMI's Quality Stands Out

- Experience Matters: 60+ years of fabrication excellence.

- In-House Expertise: From laser cutting, forming, welding, and machining to assembly, every process is handled under one roof, ensuring end-to-end control.

- Advanced Robotics: Robotic welding improves consistency and repeatability, producing tight, precise welds every time.

- Custom Manufacturing Solutions: Whether you have a fully developed blueprint or just a rough concept, our experienced team will collaborate with you to create solutions that meet your needs efficiently and affordably

How Robotic Welding Improves Quality and Consistency

LMI uses robotic welding arms for their ability to:

- Minimize human error

- Ensure consistent bead placement

- Reduce welding variability

- Achieve tighter tolerances (within ±0.2 mm in some cases)

- Ensures low possibility of weld deformation through consistent repeatable processes

The result? Higher quality welds that meet even the strictest OEM specifications.

Precision Welding vs. Standard Welding: What’s the Difference?

Precision welding requires tighter tolerances, higher consistency, and more controlled environments compared to standard welding. LMI’s welding department offers both traditional standard welding while also providing precision welding for complex assemblies — offering better structural integrity, cleaner aesthetics, and superior performance for your parts.

Monitoring of Third-Party Vendors

At LMI, our commitment to quality extends beyond the walls of our facility. While nearly all fabrication services are handled in-house, we strategically outsource finishing processes—including polishing, painting, and powder coating—to a select group of trusted local partners. These partners are chosen based on their ability to meet LMI’s strict quality standards, competitive pricing, and reliable turnaround times.

Each outsourced process is closely monitored through coordinated scheduling, daily communication, and inspection protocols to ensure consistency with your part specifications. Before any coated or finished part leaves for final delivery, our team performs visual and dimensional inspections to verify quality alignment with project requirements.

By maintaining tight oversight of outsourced services, LMI ensures that every finished product—regardless of where the final coating is applied—meets the same level of excellence you expect from our in-house operations.

By adhering to these principles, we ensure each part that leaves our facility meets your expectations — and ours.

Ready to Work With a Fabricator Who Understands Quality?

Let’s build better parts together — with quality you can see, and results you can trust.