About LMI Manufacturing

LMI is a 40,000 sq. ft. facility with a team of around 35 dedicated employees, delivering expert fabrication services with personalized attention you won’t find at a massive manufacturer.

From Our Roots in Agriculture to Advanced Fabrication – 60+ Years Strong

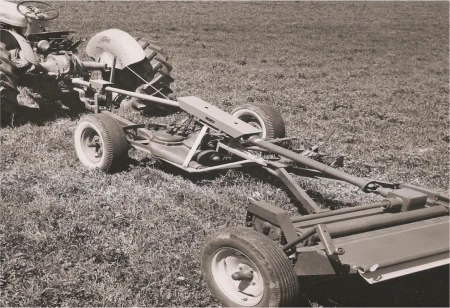

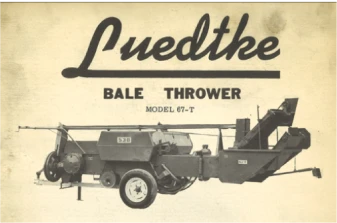

Founded in 1960 on a family farm in the Midwest, LMI Manufacturing began with a simple goal: make life easier for local farmers. Our story started with the invention of the Luedke Hay Mover/Hay Conditioner that dramatically cut down harvest time—and continued with innovative equipment like bale throwers that eventually caught the attention of companies like Ford.

Over the decades, LMI has grown from farm-based ingenuity to full-scale, professional metal fabrication, always staying true to our hands-on, customer-first approach.

As time progressed, LMI’s reputation began to be known in the community in which internationally known manufacturers asked to work with LMI within a fabrication relationship. This catapulted LMI from a small agricultural manufacturer to a full-blown welding and fabrication shop.

Today, LMI is a recently renovated 40,000 sq. ft. facility with a team of around 35 dedicated employees. Our commitment to continuous improvement and adaptability ensures that we meet the ever-changing demands of our clients.?

Lloyd Luedtke Hay Mover/Hay Conditioner Invention Source: Jim Luedtke Photo Collection

Leadership Team

Randy Hasby

President

Focuses on managing the technology and ensures the plant remains operational while making critical decisions that contribute to LMI’s success.

Marcie Gundrum

Controller

Oversees the financial management, ensuring the company’s financial health. While playing a pivotal role in LMI’s production flow.

Ryan Konicek

Owner

Purchased the company in 2018 and is responsible for growth, with a key focus on expanding LMI’s market presence adn capbilities.

Joe Swessel

Engineering Manager

Leads the engineering team to ensure every part is made to perfection and maintains high-quality standards.

Adam Bertz

Shop Manager

Manages plant operations and maintains high-quality standards at LMI. Works closely with teh staff on the floor to ensure every part is made with the utmost precision.

Company History

1960

Early Beginnings

LMI was founded in Hartford, Wisconsin, as a small job shop. During this time, Lloyd Luedtke invented the Bale Thrower, which was patented and manufactured for Ford Motors.

1969

Innovation

LMI revolutionized tractor pulling with the creation of the first mechanical tractor puller, “The Elimnator.”

1985

Lance Industries

LMI created Lance Industries, which was the first tumbler in the United States. With the creation of the tumbler, Lance industries was founded and has been serving the food processing industry for 40 years.

2018

New Ownership

LMI was purchased by new ownership, ensuring continued growth with significant expansions to the building’s infrastructure and capabilities, while maintaining the company’s strong history, customer service and culture.

2025

ISO Compliance

LMI achieves ISO Compliance, setting a new standard for quality and excellence in manufacturing.

Precision Metal Fabrication with a Human Touch

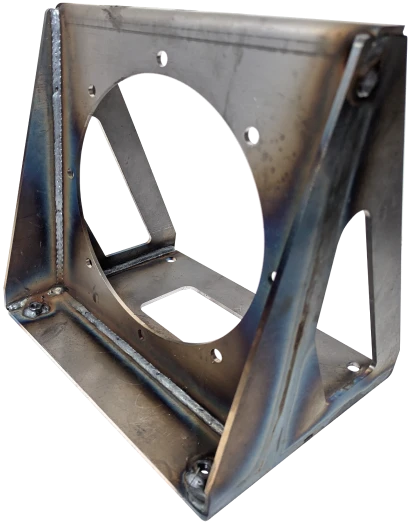

At LMI, we’re more than a metal fabricator—we’re your partner in production. Our expertise centers on three core capabilities: laser cutting, forming, and welding. These are the areas where we truly shine, delivering top-tier results with exceptional speed, quality, and consistency.

Whether it's tight-tolerance laser work, precision forming, or complex weldments, our team combines technical know-how with advanced equipment to bring your parts to life exactly as designed. From robotic welding systems to a 6kW big bed fiber laser with a large cutting bed to offline-programmed press brakes, we’re equipped for efficiency and excellence.

But our capabilities don’t stop there. We also offer a full suite of metal fabrication services under one roof, including turret punching, machining, grinding, sawing, and assembly. That means we can support your entire project, from prototype to production—seamlessly and with fewer handoffs.

No matter the complexity or volume, our goal is always the same: to deliver smart, reliable, and scalable fabrication solutions with a personal touch.

Why Customers Choose LMI

Fast, Accurate

Quotes

With our new estimating software, 80% of quotes-especially for standard materials and processes-are turned around within 24-48 hours.

On-Time

Every Time

We reserve 20% of shop capacity for emergency jobs to help customers hit critical deadlines.

Smart Shop

FLoor

Real-time dashboards show machine status, track part progress, and ensure we can promise accurate lead times prior to taking on a project.

Creative

Manufacturing

Support

Need help optimizing a part? Our team helps customers prototype and move efficiently into production.

Outstanding

Weld Quality

Our welding department is our pride and differentiator-customers regularly tell us we provide the best quality weldments they’ve received.

Built on Values. Driven by Technology.

We believe in:

Dependability & Trust

our clients know we'll come through.

Professionalism & Expertise

with a small-town feel-combined with over six decades of experience.

Collaborative Communication

because partnership and your production matters to us.

Continuous Improvement

through investments in the latest technology and process innovation.

We’re not just fabricators. We’re champions of performance and mentors in metal-offering tailored solutions, honest advice, and long-term support that helps our clients grow.

Investing in the future

LMI is embracing the next era of smart manufacturing. We’re actively investing in technology that will soon link our quoting software directly to our ERP system-paving the way for real-time insights and a fully paperless production process. Combined with recent innovations like robotic welding, part tracking, and advanced capacity planning, we’re positioning LMI to set a new standard for what a mid-size metal fabrication shop can deliver.

And we’re not stopping. We’re exploring future technologies-from AI-driven data decisions to human-assist robotics-that will enhance precision, productivity, and partnership.

Staying True to Our

Community

Though we’ve evolved into a nationwide metal fabrication partner, we never forget where we came from. Whether it's helping a local farmer with a quick weld or supporting nearby tech schools with internships and job opportunities, we stay rooted in community connection. We’re proud to offer good-paying jobs to local talent and contribute to the region’s industrial growth.

Let’s build something better – Together

Whether you’re launching a new project or looking for a more reliable fabrication partner, we’d love to hear from you. Start with a quick call or in-person visit to see if we’re the right fit. If you value quality, precision, and partnership, you’ll feel right at home with LMI.